Pure and Agile

What is an Abatement?

An abatement system is a gas processing device that treats harmful and toxic gases such as hydrochloric acid, toxic metals and gases, and volatile solvents generated in semiconductor manufacturing. It can be applied to various processes and renders waste products harmless, to provide a clean environment at semiconductor manufacturing sites.

CSK abatement systems offer products for all related process gases and provide maximum efficiency with minimal maintenance. Also, with global efforts to reduce carbon emissions and the trend towards carbon neutrality, CSK abatement is creating a world where technology and the environment can coexist as an eco-friendly solution.

- Burn-Wet Abatement

- Dry Abatement

- Plasma-Wet Abatement

Burn-Wet Abatement

The Burn-Wet Abatement System thermally decomposes and oxidizes harmful gases through a combustion process and discharges them below the acceptable level for atmospheric discharges. By providing a combustor optimized according to the process, it shows an excellent ability to reduce gas emissions with low fuel consumption.

CSK provides the latest combustion technology that can significantly reduce byproducts such as carbon monoxide (CO) and nitrogen oxides (NOx) generated after combustion. With differentiated Mean Time Between Service (MTBS) through auto-cleaning specifications and proven integrated Wet ElectroStatic Precipitator (WESP), it effectively removes solid and liquid particulates floating in contaminated gases.

CSK’s Burn-Wet abatement system is recognized for its safety, convenience, and operational stability thanks to its special modular design. After a module swap, an airtight inspection is required using pressurized nitrogen to prevent any gas leaks.

It is also equipped with various safety devices, such as gas, smoke, and fire detectors to protect users' and customers’ property.

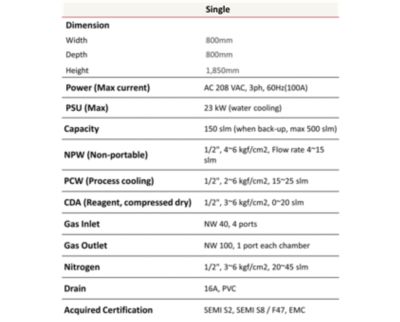

Product Details

Dry Abatement

The Dry Abatement System treats harmful gases at room temperature through chemical adsorption using dry substances. It is eco-friendly equipment that doesn’t use water which generates toxic wet sludge. It allows safe treatment of toxic gases that are not suitable for treatment with other types of abatement.

CSK’s Dry abatement is a safe abatement system that meets accredited international standards maximizing user convenience and safety through digital controls. It safely manages resin replacement cycles by applying an emission detection system (End Point Detector). It is also user-friendly equipment that can guarantee 100% operating time through a small absorber when replacing resins that have been used.

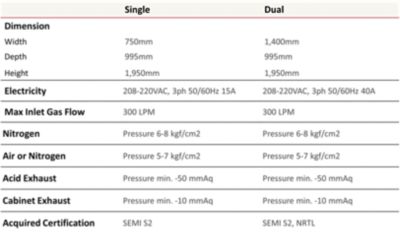

Product Details

Plasma-Wet Abatement

Our Plasma-Wet Abatement System decomposes and purifies PFC gases through thermal plasma, generated by arc discharge. In line with challenges for carbon neutrality faced by the semiconductor and display industries, it is an eco-friendly abatement system that provides highly efficient performance without using fossil fuels. Since it is a facility that can be operated only with nitrogen, air, and water, once the electrical supply is secured, it can be operated at a low initial installation cost.

CSK’s Plasma-Wet abatement system secures low-power, high-capacity processing technology and improved by-product emission, through a phased product improvement roadmap. We are also making efforts to reduce product operating costs by optimizing utility use.

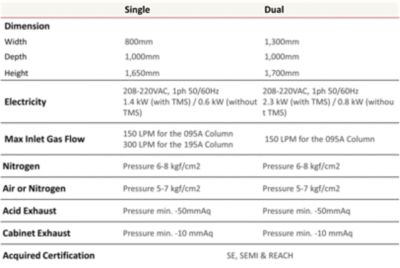

Product Details